Health hazards in the electronics industry tend to vary depending on your definition of electronics – semiconductor manufacturing involves some exotic and dangerous chemicals such as arsine, phosphine and silane (all of which can spontaneously combust in air) as dopants and some extremely aggressive acids and oxidisers such as Hydrogen Chloride (HF) and even Chlorine Trifluoride (ClF3) for etching and other surface treatments.

Health hazards in the electronics industry tend to vary depending on your definition of electronics – semiconductor manufacturing involves some exotic and dangerous chemicals such as arsine, phosphine and silane (all of which can spontaneously combust in air) as dopants and some extremely aggressive acids and oxidisers such as Hydrogen Chloride (HF) and even Chlorine Trifluoride (ClF3) for etching and other surface treatments.

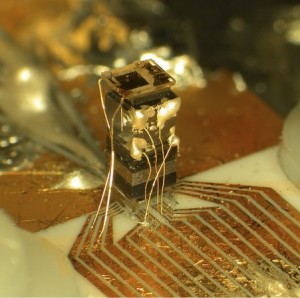

Moving a little further up the manufacturing chain are some hazards many are more familiar with – soldering traditionally uses a large percentage of lead, and inhalation and accidental ingestion can quickly cause blood lead levels to increase – and of course blood lead testing must be carried out for anyone at a high risk of exposure. Luckily lead has been phased out of most solders, though sometimes at the cost of more rosin-based flux, the resin acids of which are potent respiratory and skin sensitisers, meriting a top-five position in the occupational asthmagen hall of fame.

Exposure to other heavy metals can also be an issue, as of course can exposure to organic solvents, indeed the propensity of n-hexane to cause peripheral neuropathy was discovered only relatively recently, amongst Chinese workers wiping the screens of smartphones and other electronic devices.

Long periods at one station, repetitive tasks and uncomfortable postures pose ergonomic issues for some employees in the industries.

- Lead and heavy metal inhalation and surface contamination assessment

- Resin acid exposure and risk assessment

- Advice and appraisal of solder fume control methods

- Safe solvent procedure, appropriate levels of control, PPE etc.

- Exposure to acid mists

Useful Resources and Links: